| Availability: | |

|---|---|

| PDF Export | |

U-L6040P

UNIQUE CNC

Generally, laser-based hole processing depends on the laser beam’s diameter—specifically, the beam is focused onto a single point to create holes. For holes larger than the beam diameter, however, a circular beam cutting technique is used instead. That said, circular laser beam scanning is time-consuming and far less efficient when compared to processes like press punching. Even so, press punching itself presents challenges: processing holes in resin films and metal foils via this method is a highly sophisticated task, requiring specialized expertise in areas such as die 3. manufacturing, die maintenance, and punching technique.

1. Roll to roll production.

2. The laser can cut any shapes.

3. No punching die required!

4. Low maintenance cost.

5. Easy operation.

| Model No. | U-L6040P |

| Table size (X * Y) | 600*400mm |

| Laser power | 80W |

| Resetting positioning accuracy | 0.01mm |

| Voltage | 220V/50HZ or 110V/60HZ |

| Operating temperature | 0 - 45°C |

| Operating humidity | 5-95% |

| Graphic format supported | *.plt, *.dst, *.dxf, *.dwg, *.ai |

| Accessories | Water chiller, air pump, exhaust fan |

1. CNC controller

2. English software

RD works files can plug-in Coreldraw and autoCAD, thus Coreldraw or autoCAD can operate the machine directly.

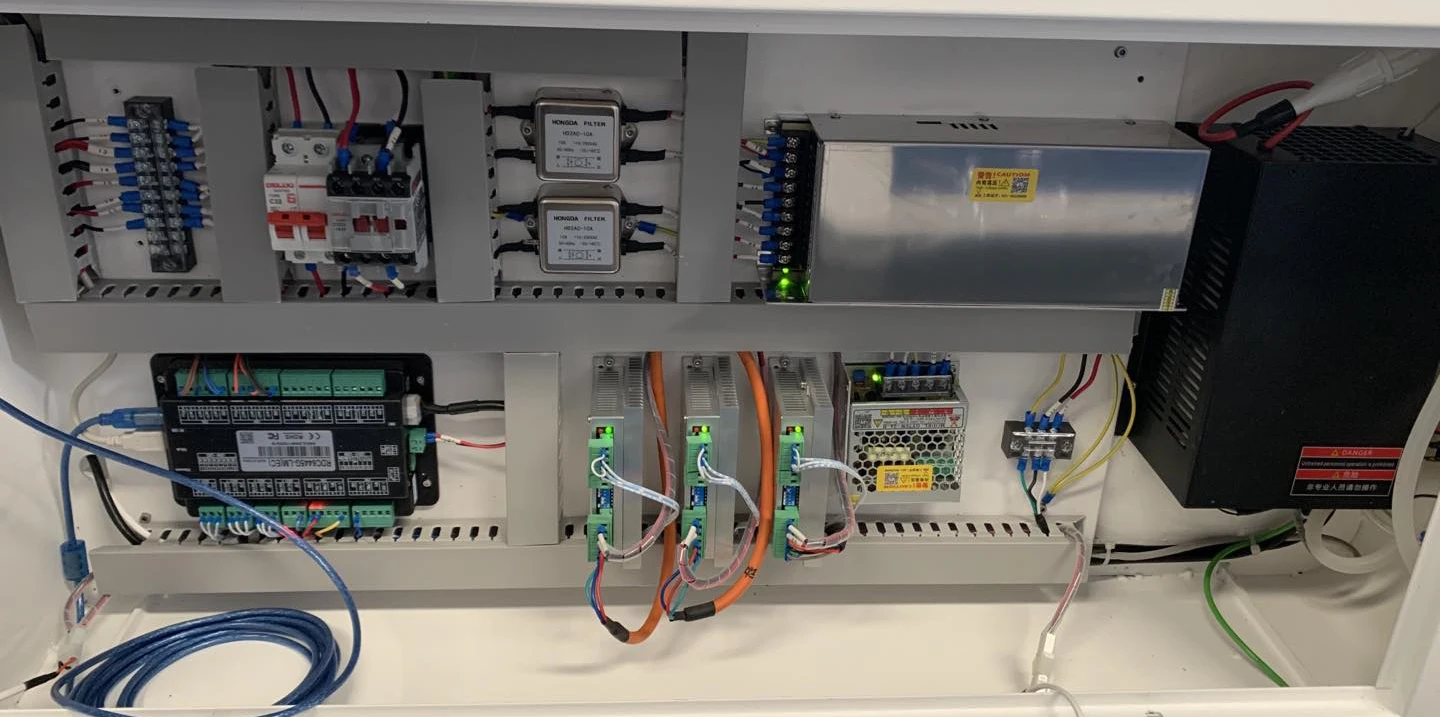

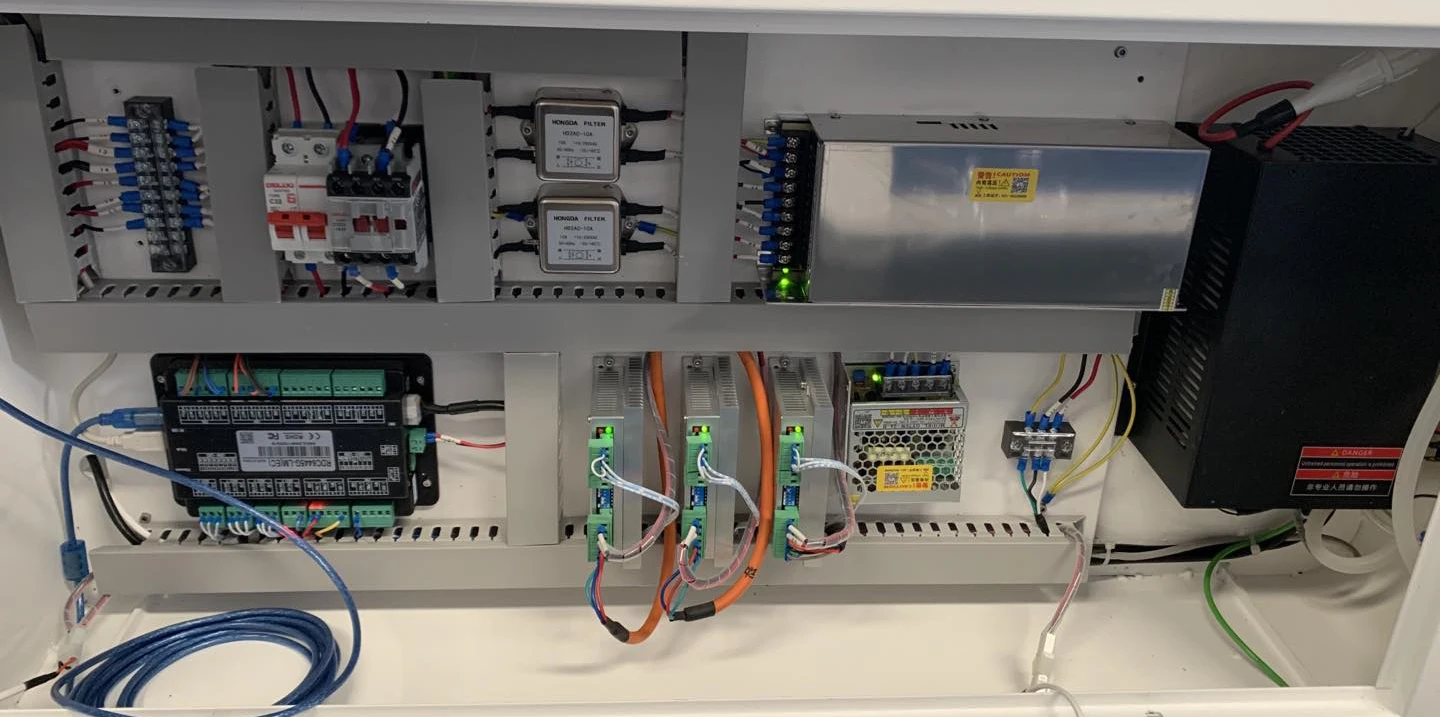

3. Well-organized electrical components

All the components are famous brand and top quality.

4. Taiwan made guide rails, on top of strong aluminum stands.

Generally, laser-based hole processing depends on the laser beam’s diameter—specifically, the beam is focused onto a single point to create holes. For holes larger than the beam diameter, however, a circular beam cutting technique is used instead. That said, circular laser beam scanning is time-consuming and far less efficient when compared to processes like press punching. Even so, press punching itself presents challenges: processing holes in resin films and metal foils via this method is a highly sophisticated task, requiring specialized expertise in areas such as die 3. manufacturing, die maintenance, and punching technique.

1. Roll to roll production.

2. The laser can cut any shapes.

3. No punching die required!

4. Low maintenance cost.

5. Easy operation.

| Model No. | U-L6040P |

| Table size (X * Y) | 600*400mm |

| Laser power | 80W |

| Resetting positioning accuracy | 0.01mm |

| Voltage | 220V/50HZ or 110V/60HZ |

| Operating temperature | 0 - 45°C |

| Operating humidity | 5-95% |

| Graphic format supported | *.plt, *.dst, *.dxf, *.dwg, *.ai |

| Accessories | Water chiller, air pump, exhaust fan |

1. CNC controller

2. English software

RD works files can plug-in Coreldraw and autoCAD, thus Coreldraw or autoCAD can operate the machine directly.

3. Well-organized electrical components

All the components are famous brand and top quality.

4. Taiwan made guide rails, on top of strong aluminum stands.

content is empty!